Table of Contents

- 1. Operators Working at Heights Beyond Their Reach

- 2. Your Operators Are Complaining About Downtime

- 3. Your Worksites Have Changed

- 4. Your Team is Growing

- 5. You’re Struggling to Meet Modern Safety and Compliance Standards

- What Upgrading Can Do for Your Business

- Not Sure if it’s Time to Upgrade your EWP? Here’s the Quick Test

- Talk to Altequip About Upgrading your EWP

How do you know when it’s time to upgrade your EWP? When your business gets its first elevated work platform, it’ll fit the job you need it to at the time. Reliable and affordable, you buy it knowing you’ll get years of use from it.

The years pass by, and your EWP has no doubt served you well. But as your business has developed, has your machine kept up with what you do?

Clients and worksites change and the jobs you take on evolve, and maybe your EWP just doesn’t tick all the right boxes anymore.

If you’re noticing inefficiencies seep in to your operations, maybe its time to ask the question:

Has your business outgrown its current EWP?

Here are the five signs that say it just might have.

1. Operators Working at Heights Beyond Their Reach

The jobs are getting taller

Every industry faces natural growth – from new lighting standards to more mature tree canopies, larger signage to higher utility lines. If your operators are often working at the upper limits of their boom, there’s no margin for error and that’s not a safe way to work at heights.

Productivity drops because you either have to set up extra equipment or hire a larger EWP in.

If this only happens on rare occasions its something you can deal with. If it’s a regular occurrence, you need to think about upgrading your EWP.

Don’t work on the edge

Working with your EWP boom at full stretch is technically possible, but it comes with risks for the operator and places extra stress on your machine. If the team is always saying “We can almost reach it…” you’ve already outgrown your machine.

2. Your Operators Are Complaining About Downtime

More breakdowns, more lost hours

Older EWPs reach a point where repairs become a regular headache. Every breakdown means you’re losing out on billable time, plus dealing with the expense of getting the machine fixed. That’s more than just a nuisance.

Listen to your operators – they’ll tell you if the machine is letting them down. If the feedback is largely negative, the issue is more likely with the platform than with your crew.

Hard-to-source parts and ageing hydraulics

Some older units become difficult or expensive to keep running simply because the parts availability dries up. Machines that can’t be serviced efficiently can’t be relied upon.

3. Your Worksites Have Changed

New terrain and tighter spaces

The business you run today might look nothing like the one you had when you purchased your current EWP. Maybe you’re doing more shopping centre work than highway signage. Or most of your clients are suburban city councils instead of large rural businesses.

The change in clientele and workspaces could mean a change in machinery is required. Your EWP should be helping you get around obstacles, not creating more for you to work with.

More manoeuvrability required

If you’ve started working in tighter spaces, the large truck-mounted EWP you once relied on is going to struggle to give you access. If you’re parking it further away and stretching the boom to its capacity to get to the job, you’re increasing your risks and wasting time in the process.

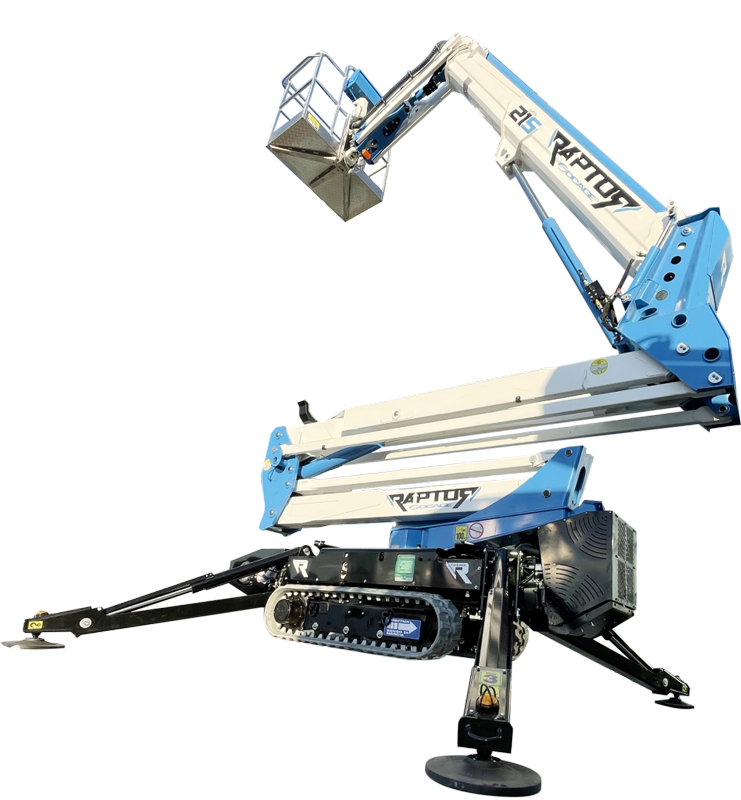

A modern platform like one of the Socage Spiders offers solid outreach, improved controls, and smarter stabilisation systems tailored for tight or complex sites. If it’s agility you need, they would be a good direction to head in.

4. Your Team is Growing

A single unit is holding up jobs

Growth brings opportunity but also exposes bottlenecks. If you have multiple teams or operators needing the same EWP, having a single asset is a choking point in your operations.

You could hire additional EWPs to temporarily cover the gap, but you may find growing your own fleet is the more cost-effective option.

Higher demand for simultaneous work

When you’ve got two or three jobs that all require height access and only one EWP to go around, you’re forced into compromises. You rush through jobs or you overwork your team. If this sounds familiar, your EWPs aren’t keeping up with your operations.

Of course, these are signs that your business is enjoying success. Your success just needs the right tools to keep it on the right path.

5. You’re Struggling to Meet Modern Safety and Compliance Standards

New legislation, old machines

Safety standards aren’t static. AS/NZS requirements evolve to match new risks, technologies and industry expectations. If your EWP predates recent compliance changes, you may want to think about an upgrade.

Auditors, insurers and clients are increasingly unforgiving. If your elevated work platforms don’t meet current standards, you’re operating in a grey area that could bite hard when something goes wrong.

Paperwork fatigue and audit risk

Older machines often lack integrated data, automated logs or easy traceability. That means more manual paperwork and more room for error. If your EWP creates admin headaches every time someone asks for compliance evidence, it’s not the right fit for a modern business.

What Upgrading Can Do for Your Business

A newer or more capable EWP can deliver tangible improvements:

- Better height and outreach for more job types

- Reduced downtime and predictable servicing costs

- Faster site setup and improved operator comfort

- Compliance confidence during audits and tenders

- The ability to take on bigger, higher-value contracts

The expense of the upgrade is balanced by the increase in capacity.

Not Sure if it’s Time to Upgrade your EWP? Here’s the Quick Test

If you answer yes to any of these questions, it’s time to reassess the EWPs you’re currently running.

- Jobs are running late waiting for the machine

- You’re reaching the boom and basket limits regularly

- Repair bills are rising each year

- Operators complain about reliability

- You’ve grown your team but not your fleet.

Talk to Altequip About Upgrading your EWP

As a business owner running EWPs, you want them to be safe, practical and reliable. If they’re not, it’s time to upgrade. Businesses at their point in their growth journey can turn to the Altequip team to guide them through the next stage in their working at heights journey.

Whether it’s a Spider Raptor or a truck-mounted EWP, we’ll help you land on the right size EWP, with the right features for the jobs you will be doing. We want your platform to support your growth and not restrict it.

Any questions at all, get in touch with our friendly team today!