Table of Contents

When you’re working off the ground, the risk level goes up too. The last thing you want is a fall from tens of metres high – it would mean serious injury or worse. Safety has to be the number one priority on elevated work platforms – you need to know your machine is doing its part in protecting your team and site from harm.

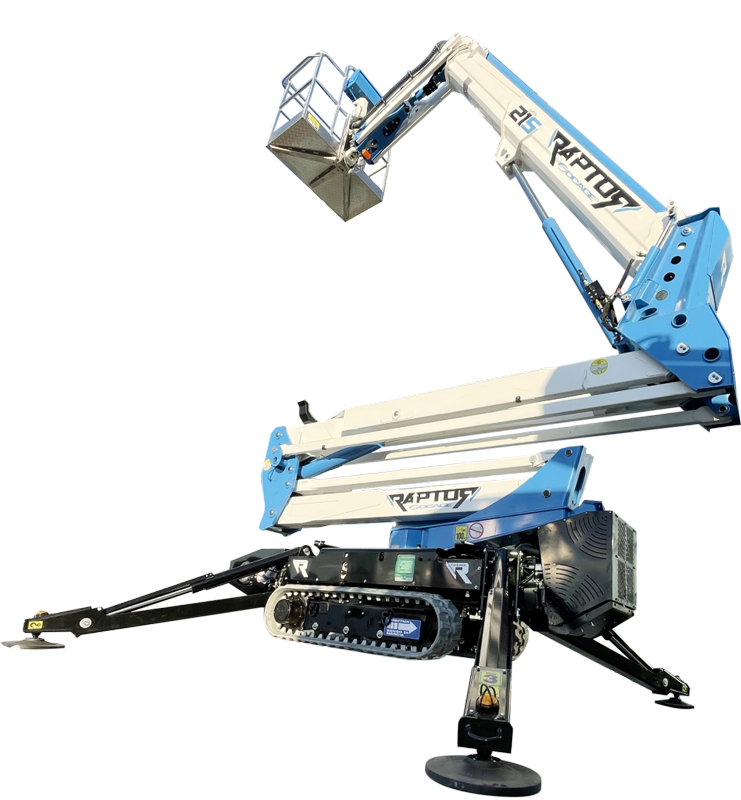

The safety features of the Socage Raptors are incredible. Over the years, they’ve built more and more layers of protection into the spider lifts. Operators today can use them with confidence, knowing they are as safe as can be thanks to smart features covering stability, control and emergency responses.

We’re going to take a look at some of these features today and show you why the Socage Raptor is the safe choice if you’re in the market for a new EWP!

Socage Raptor Safety Features

Automatic Stabilisation

Being steady and stable is essential for safety when working above the ground. The Raptors have large automatic stabilisers that extend outwards to form a solid base (they resemble spider’s legs, hence the name ‘spider lifts’). The outriggers are easy to operate – you simply press a button and out they go.

This is a big deal on tricky terrain – you can stabilise the platform quickly and know that the load will be evenly supported. The system constantly monitors the position of the outriggers too, so it won’t let you operate if it senses a risk of tipping.

Emergency Lowering System

If something goes wrong while working at heights you need to get that basket back down safely. Socage includes a manual emergency descent system on all recent models. Even if power fails or electronics stop responding, you can still lower the boom and platform using the backup controls.

The operator won’t be stuck up high waiting for rescue – maintenance crews can bring the machine down safely if there’s a problem.

Overload Protection

Spider lifts and other EWPs have weight limits for safety reasons – too much load affects balance and structural integrity. Socage has integrated overload sensors into the baskets of its Raptor lifts, which detect when the weight limit has been reached. If it is, they stop the platform from going higher!

To stop that from happening, Socage integrates overload sensors into the basket. These sensors detect when the limit’s been reached and lock the platform from moving higher.

Emergency Stop Buttons

Fast access to a stop button can save lives. Socage installs emergency stop controls in both the basket and at the base of the lift. Either operator can hit it, instantly cutting power to the hydraulics and halting all movement.

This quick control of the machine can help lock everything down if the unexpected happens. These buttons have helped prevent many accidents from happening or from being worse than they could have been.

Tilt and Inclination Sensors

Worksites are unpredictable and even the spider leg stabilisers need support sometimes. That comes in the shape of tilt and inclination sensors. These constantly monitor the lean of the machine. If it goes past a certain point, no further movement will be allowed until the problem is fixed.

This feature helps keep the operation of the Raptor Spider within the safe range the manufacturer has decided on.

Automatic Speed Control

One of the big drawcards of the Raptors is they’re great at working in tight or confined spaces. To do this successfully, you need control, and a big part of that is being able to control the speed of movement of the boom. Socage has implemented automatic speed control that adjusts how fast the boom moves depending on how far it’s extended.

Working right up high or with the boom out wide? The movement will be more precise without any sudden movements that could throw the operator in the basket off balance.

Guard Rails and Harness Points

Every platform is surrounded by solid guardrails to prevent falls. They’re built to meet international safety standards and are part of the reason why spider lifts are far safer than ladders or scaffolds.

On top of that, there are harness anchor points welded into the basket. Operators clip in with an approved lanyard, giving them a second layer of fall protection. If they slip or lose footing, the harness keeps them inside the basket.

Non-Slip Platform Surface

When you’re working outdoors, the platform can get dusty, wet or greasy. The non-slip surface on Socage baskets gives better traction underfoot, even in poor conditions. It’s one of those small design choices that make daily use safer and more comfortable.

Remote and Ground Controls

There are two sets of controls on each raptor: one in the basket and one at ground level. The second set lets someone on the ground operate or override the lift if needed.

Loading and transporting the elevated work platform via remote is also safer, because you can control it externally.

Safety Monitoring and Diagnostics

Modern spider lifts aren’t just mechanical anymore. Socage uses onboard diagnostics to keep an eye on system performance and detect issues early. You’ll get alerts if something isn’t working as expected, whether it’s a hydraulic fault, sensor issue or power warning.

Their newer “My Socage” system also allows remote support and software updates. That means fewer breakdowns, faster servicing and up-to-date safety logic in the control system.

See a Socage Spider Lift in Action

Altequip is the official agent for Socage EWPs in Australia. When we say these are the safest spider lifts on the market, it’s because we know these machines inside out. They’re not just safe – they’re tough, reliable and get the job done.

We’d love to demonstrate one for you. Get in touch and let’s organise a time to do so at our North Brisbane branch.

FAQs

1. Do Socage spider lifts need regular safety inspections?

Yes. Like all EWPs, spider lifts need routine inspections and servicing, including a major inspection every ten years.

2. Can spider lifts be used on uneven or sloped ground?

Yes, but only within limits. The automatic stabilisation system and tilt sensors help level the lift, but if the slope is beyond the rated angle, the machine won’t operate.

3. What happens if the power fails while the lift is in the air?

Every Socage spider lift includes a manual emergency descent system. You can lower the EWP basket safely to the ground without relying on the main electrical or hydraulic power.

4. Are operators required to wear a harness?

Yes. While the guard rails provide physical protection, operators must wear a full-body harness attached to the anchor point inside the basket. It’s a legal requirement under Australian work-at-height safety rules.

5. Can spider lifts be used indoors?

They can. Socage’s electric and hybrid models are ideal for indoor use because they run quietly and produce zero emissions. Be sure to check the weight-bearing capacity of the floors before commencing work.